Graphite Hot Pressing Mold Used For Pressure Sintering Of Cemented Carbide

lttrade.en.made-in-china.comA: Company profile

L.T Group has a comprehensive product and technology portfolio that focuses on four

fields of graphite - ultrafine particle graphite mould, graphite electrode, graphite crucible,

as well as other products mainly made of graphite.

Graphite materials exhibit unique properties such as good electrical and thermal

conductivity, heat and corrosion resistance, low friction, and reduced weight while at

the same time maintaining high strength. Due to the shortage of energy and raw materials,

our high performance products made from graphite are in increasingly high demand in

industries. They also play a progressively important role in everyday life, thereby

substituting traditional materials.

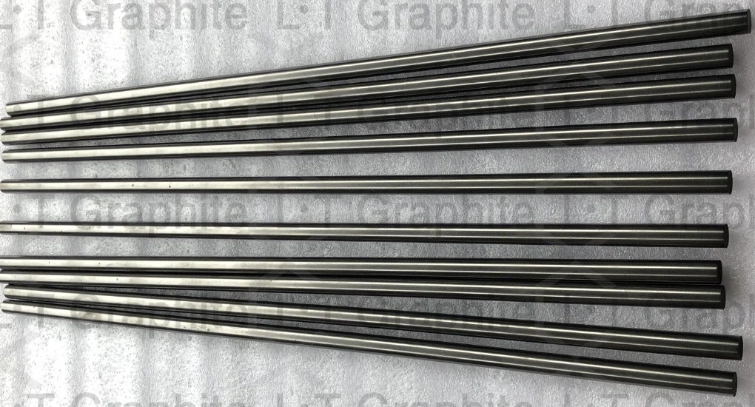

B: Product features

1. The processing materials are ultrafine granule structure, high purity and graphite

with high graphitization degree.

2. High hardness, good anti-oxidation performance and high machining accuracy

3. Good conductivity, high resistivity, sufficient mechanical strength

4. Small porosity and dense structure.

5. Excellent thermal shock resistance, conductive and thermal conductivity.

6. High temperature resistance, corrosion resistance, acid and alkali resistance,

good wear resistance.

7. Surface can be treated with anti-oxidation.

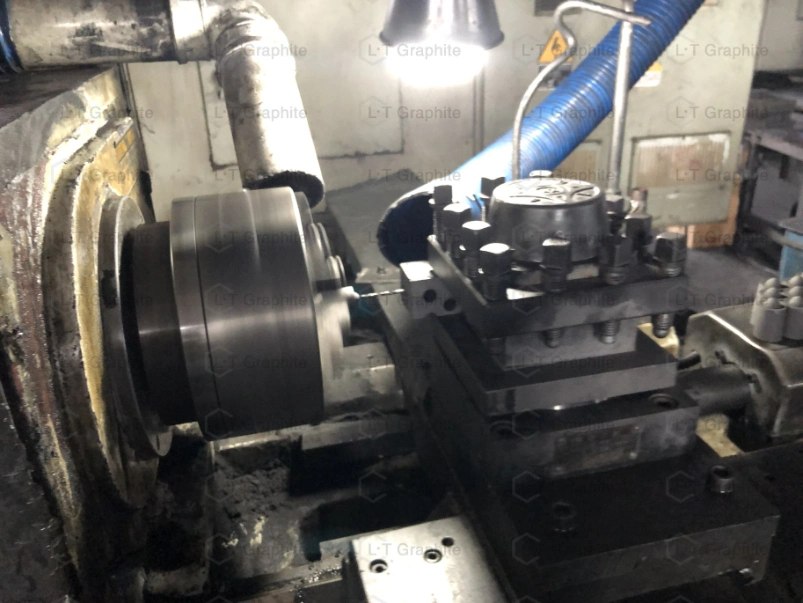

C: Processing method

1. Customer provide design drawings.

2. Our technical team will check, analyze the drawings, and divide the drawing to

reasonable parts if needed, and prepare proper graphite blocks .

3. Our mechanics will design and customize grinding wheel.

4. Our workers will grinding and polishing graphite block according to the instructions

of mechanics. This process may need operating few times if needed. We will strictly keep

deviation within ±0.03-0.08mm.

5. Then our packing team will assembling different parts into a whole graphite mold.

During the assembling period, unqualified products will be picked out.

D: Attribute table

| Density g/cm³ | 1.75-1.9 |

| Resistivity μΩ·m | ≤18 |

| Compressive strength Mpa | 40-80 |

| Porosity % | ≤26 |

| Elasticity Modulus Gpa | 6-18 |

| Thermal expansion coefficient 10-6/ºC | 1.47-4.25 |

| Ash content % | ≤0.5 |

| Temperature resistance ºC | ≤4350 |