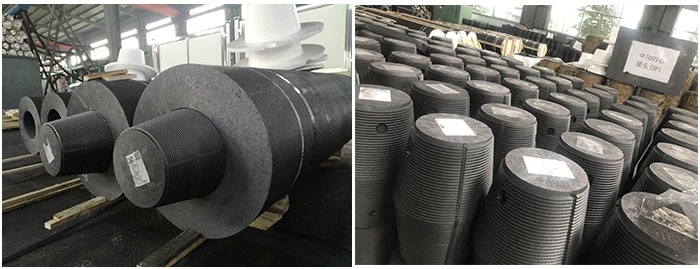

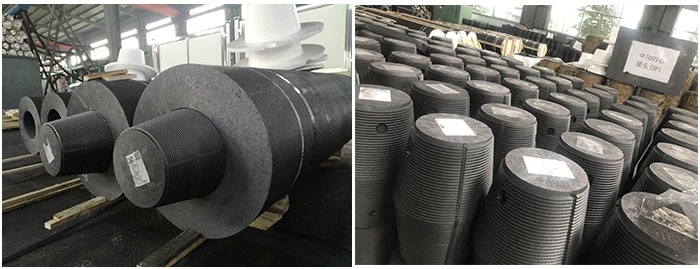

UHP HP RP 12/14/16/18/20/22 Inch Graphite Electrode with Nipple from Rongxing Group

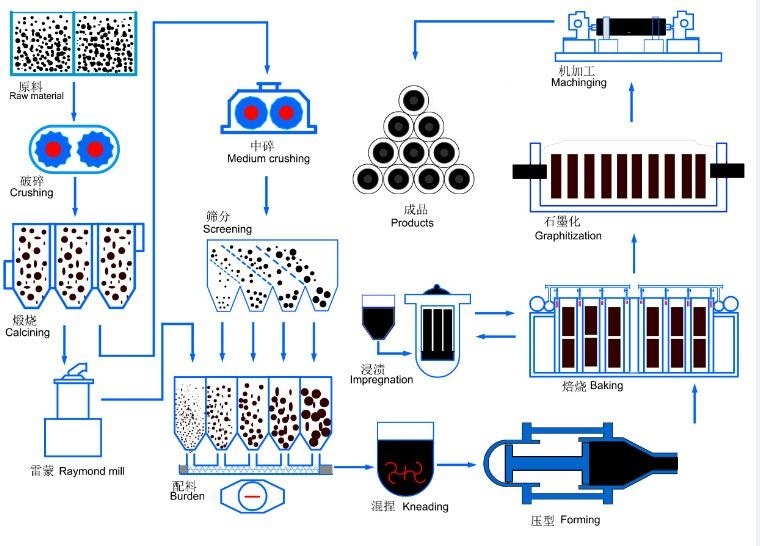

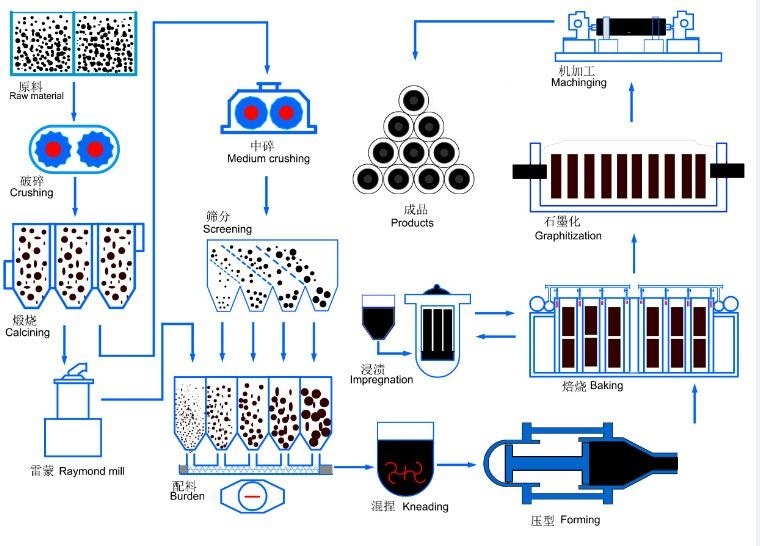

Rongxing graphite electrode grades RP, HP, SHP, UHP is mainly made of petroleum coke and needle coke. The product is being made through the process of calcination, compounding, kneading, pressing, baking, impregnation, graphitization and machining. It is a conductor that release electrical energy to heat and melt the charge in the form of an electric arc in an electric arc furnace, and has the characteristics of low electrical resistivity, good electrical conductivity, low ash, uniform structure, good oxidation resistance and high mechanical strength.

Application of Rongxing UHP HP RP 12/14/16/18/20/22 Inch Graphite Electrodes with High Bulk Density

1. Rongxing Graphite Electrode with Nipple is being used in electric arc steelmaking furnace Graphite electrode is mainly used in electric furnace steelmaking. Electric furnace steelmaking uses graphite electrodes to introduce current into the furnace. A strong current generates an arc discharge through the gas at the lower end of the electrode, and uses the heat generated by the arc to smelt.

2. Rongxing Graphite Electrode with Nipple is being used in ore-heating furnaces Graphite electrode ore-heating furnaces are mainly used to produce ferroalloys, pure silicon, yellow phosphorus, matte and calcium carbide, etc., which is characterized by electrical conductivity.

3. For resistance furnaces, graphitization furnaces for producing graphite products, melting furnaces for melting glass, and electric furnaces for producing silicon carbide are all resistance furnaces.

4. Used for processing a large number of graphite electrode blanks; also used for processing into various crucibles, graphite boats, hot die casting molds and heating elements for vacuum electric furnaces, etc.

Parameter for UHP HP RP 12/14/16/18/20/22 Inch Graphite Electrode with Nipple

Current load and current density:

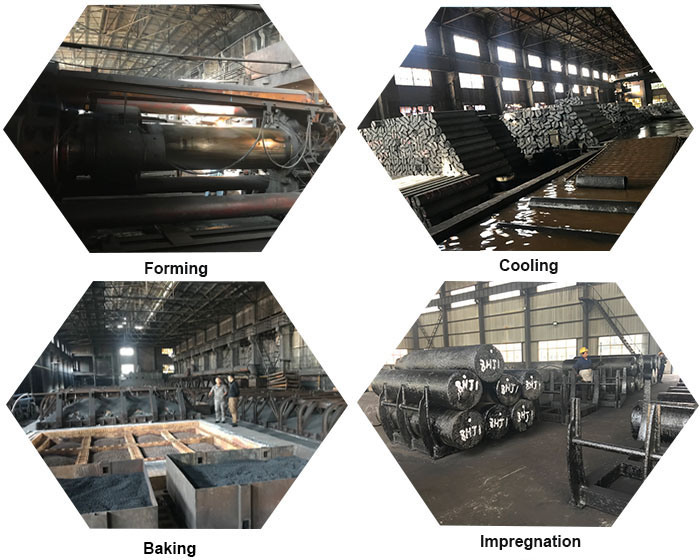

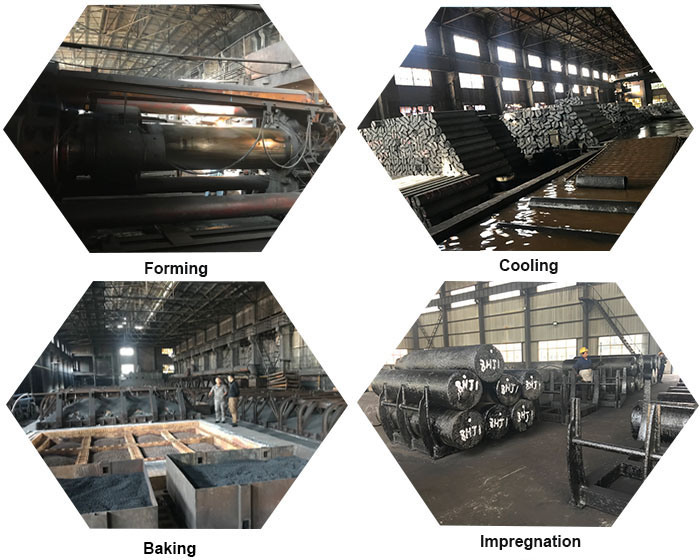

Processing for Graphite Electrode with Nipple

World's Leading Graphite Electrode with Nipple Manaufacturer-Rongxing Group

Rongxing Group manufactures and supplies high quality Graphite Electrode with Nipple and electrode paste to international market. Our ISO 9001 certification registered production facilities are emblematic of Rongxing's ongoing commitment to quality and sustainability in the manufacture of these products. The company maintains stringent quality processes and standards in the industry to ensure an effective Quality Management System, continual improvements, and excellence in customer satisfaction.

Rongxing holds itself to the highest quality standards that control everything from incoming raw materials to final factory production. At Rongxing, all materials are tested to ensure they meet industry standards before entering the manufacturing phase. Additionally, every Rongxing lab is ISO9001 accredited for all routine QC tests performed at each facility.

Customer satisfaction comes first at Rongxing. Our goal is to continually improve our products, services and our quality management system by establishing and reviewing quality objectives on a consistent basis. It possesses sophisticated manufacturing and inspection equipment, provides 100% inspection and reporting on each product delivered to its customers so you can be assured that 100% of your parts are manufactured and tested to the highest quality standards.

As an influential and responsible supplier, we are able to provide our customers with more thoughtful services and technical support.Our graphite electrode and electrode paste have strong presence in world market, which enjoys very good reputation.Manaufacturer-Rongxing Group

Rongxing Group manufactures and supplies high quality graphite electrode and electrode paste to international market. Our ISO 9001 certification registered production facilities are emblematic of Rongxing's ongoing commitment to quality and sustainability in the manufacture of these products. The company maintains stringent quality processes and standards in the industry to ensure an effective Quality Management System, continual improvements, and excellence in customer satisfaction.

Rongxing holds itself to the highest quality standards that control everything from incoming raw materials to final factory production. At Rongxing, all materials are tested to ensure they meet industry standards before entering the manufacturing phase. Additionally, every Rongxing lab is ISO9001 accredited for all routine QC tests performed at each facility.

Customer satisfaction comes first at Rongxing. Our goal is to continually improve our products, services and our quality management system by establishing and reviewing quality objectives on a consistent basis. It possesses sophisticated manufacturing and inspection equipment, provides 100% inspection and reporting on each product delivered to its customers so you can be assured that 100% of your parts are manufactured and tested to the highest quality standards.

As an influential and responsible supplier, we are able to provide our customers with more thoughtful services and technical support.Our graphite electrode and electrode paste have strong presence in world market, which enjoys very good reputation.

Please feel free to contact us if any enquiry for Graphite Electrode grades RP, HP, SHP, UHP for Steel Making.

Rongxing graphite electrode grades RP, HP, SHP, UHP is mainly made of petroleum coke and needle coke. The product is being made through the process of calcination, compounding, kneading, pressing, baking, impregnation, graphitization and machining. It is a conductor that release electrical energy to heat and melt the charge in the form of an electric arc in an electric arc furnace, and has the characteristics of low electrical resistivity, good electrical conductivity, low ash, uniform structure, good oxidation resistance and high mechanical strength.

Application of Rongxing UHP HP RP 12/14/16/18/20/22 Inch Graphite Electrodes with High Bulk Density

1. Rongxing Graphite Electrode with Nipple is being used in electric arc steelmaking furnace Graphite electrode is mainly used in electric furnace steelmaking. Electric furnace steelmaking uses graphite electrodes to introduce current into the furnace. A strong current generates an arc discharge through the gas at the lower end of the electrode, and uses the heat generated by the arc to smelt.

2. Rongxing Graphite Electrode with Nipple is being used in ore-heating furnaces Graphite electrode ore-heating furnaces are mainly used to produce ferroalloys, pure silicon, yellow phosphorus, matte and calcium carbide, etc., which is characterized by electrical conductivity.

3. For resistance furnaces, graphitization furnaces for producing graphite products, melting furnaces for melting glass, and electric furnaces for producing silicon carbide are all resistance furnaces.

4. Used for processing a large number of graphite electrode blanks; also used for processing into various crucibles, graphite boats, hot die casting molds and heating elements for vacuum electric furnaces, etc.

Parameter for UHP HP RP 12/14/16/18/20/22 Inch Graphite Electrode with Nipple

| Items | RP Grade | HP Grade | UHP Grade | ||||

| Specification | Electrode | Nipple | Electrode | Nipple | Electrode | Nipple | |

| RESISTIVITY μΩΜ | < 7.8 | < 6.8 | < 7.0 | < 5.5 | < 5.5 | < 5.0 | |

| BENDING STRENGTH Mpa | > 8.4 | > 13.5 | > 10 | > 14 | > 11 | > 17 | |

| ELASTIC MODULVS Gpa | < 9.3 | < 14 | < 12 | < 14 | < 14 | < 18 | |

| BULKDENSITY g/cm3 | > 1.58 | > 1.72 | > 1.66 | > 1.72 | > 1.70 | > 1.76 | |

| CTE 10-6/ºC | < 2.8 | < 2.7 | < 2.5 | < 2.2 | < 1.4 | < 1.3 | |

| ASH % | < 0.5 | < 0.5 | < 0.3 | < 0.3 | < 0.2 | < 0.2 | |

Current load and current density:

| Diameter | RP | HP | UHP | |||

| mm | Current Load (A) | Current Density(A/cm³) | Current Load (A) | Current Density(A/cm³) | Current Load (A) | Current Density(A/cm³) |

| 200 | 5000-6900 | 15-21 | 5500-9000 | 18-25 | ||

| 225 | 6100-8600 | 15-21 | 6500-10000 | 18-25 | ||

| 250 | 7000-10000 | 14-20 | 8000-13000 | 18-25 | 8100-12200 | 20-30 |

| 300 | 10000-13000 | 14-18 | 13000-17400 | 17-24 | 15000-22000 | 20-30 |

| 350 | 13500-18000 | 14-18 | 17400-24000 | 17-24 | 20000-30000 | 20-30 |

| 400 | 18000-23500 | 14-18 | 21000-31000 | 16-24 | 25000-40000 | 19-30 |

| 450 | 22000-27000 | 13-17 | 25000-40000 | 15-24 | 32000-45000 | 19-27 |

| 500 | 25000-32000 | 13-16 | 30000-48000 | 15-24 | 38000-55000 | 18-27 |

| 550 | 32000-40000 | 13-16 | 37000-57000 | 15-23 | 42000-66000 | 17-26 |

| 600 | 38000-47000 | 13-16 | 44000-67000 | 15-23 | 49000-76000 | 17-26 |

Processing for Graphite Electrode with Nipple

World's Leading Graphite Electrode with Nipple Manaufacturer-Rongxing Group

Rongxing Group manufactures and supplies high quality Graphite Electrode with Nipple and electrode paste to international market. Our ISO 9001 certification registered production facilities are emblematic of Rongxing's ongoing commitment to quality and sustainability in the manufacture of these products. The company maintains stringent quality processes and standards in the industry to ensure an effective Quality Management System, continual improvements, and excellence in customer satisfaction.

Rongxing holds itself to the highest quality standards that control everything from incoming raw materials to final factory production. At Rongxing, all materials are tested to ensure they meet industry standards before entering the manufacturing phase. Additionally, every Rongxing lab is ISO9001 accredited for all routine QC tests performed at each facility.

Customer satisfaction comes first at Rongxing. Our goal is to continually improve our products, services and our quality management system by establishing and reviewing quality objectives on a consistent basis. It possesses sophisticated manufacturing and inspection equipment, provides 100% inspection and reporting on each product delivered to its customers so you can be assured that 100% of your parts are manufactured and tested to the highest quality standards.

As an influential and responsible supplier, we are able to provide our customers with more thoughtful services and technical support.Our graphite electrode and electrode paste have strong presence in world market, which enjoys very good reputation.Manaufacturer-Rongxing Group

Rongxing Group manufactures and supplies high quality graphite electrode and electrode paste to international market. Our ISO 9001 certification registered production facilities are emblematic of Rongxing's ongoing commitment to quality and sustainability in the manufacture of these products. The company maintains stringent quality processes and standards in the industry to ensure an effective Quality Management System, continual improvements, and excellence in customer satisfaction.

Rongxing holds itself to the highest quality standards that control everything from incoming raw materials to final factory production. At Rongxing, all materials are tested to ensure they meet industry standards before entering the manufacturing phase. Additionally, every Rongxing lab is ISO9001 accredited for all routine QC tests performed at each facility.

Customer satisfaction comes first at Rongxing. Our goal is to continually improve our products, services and our quality management system by establishing and reviewing quality objectives on a consistent basis. It possesses sophisticated manufacturing and inspection equipment, provides 100% inspection and reporting on each product delivered to its customers so you can be assured that 100% of your parts are manufactured and tested to the highest quality standards.

As an influential and responsible supplier, we are able to provide our customers with more thoughtful services and technical support.Our graphite electrode and electrode paste have strong presence in world market, which enjoys very good reputation.

Please feel free to contact us if any enquiry for Graphite Electrode grades RP, HP, SHP, UHP for Steel Making.