Product Discription:

Natural graphite is sintered with flake graphite and earthy graphite, and its carbon content reaches 99% ~ 99.99%.

Oriented film: Graphite film using advanced technology to make high-purity graphite materials to regular orientation structure

Quick Details:

| Place of Origin: | Hebei, China | Brand Name: | XS |

| Type: | Flexible Sheet | Application: | Smart phones, table PCs, LED |

| Grade: | Industrial Grade | C Content(%): | 99.9% |

| thermal conductivity (X-Y-axis): | 300-700w/mk | surface character: | flexible diaphragm |

| density: | 1.3-1.5g/cm3 | hardness: | 85 ShoreA |

| tensile strength: | 650psi | UL flammability rating: | 94VO |

| temperature resistance: | - 40ºC to 400ºC |

Supply Ability:

50000 Square Meters/Month

Port: Tianjin, China

Packing: Plastic bag and carton or wooden case.

Lead Time : 15-35 days after advanced payment.

Features of natural graphite sheet:

* Excellent thermal conductivity: up to 500W/m·K

* Lightweight: Specific gravity: 0.87 to 1.6 g/cm3 (30% lighter than aluminum, 80% lighter than copper in the same size)

* Low thermal resistance, 40% lower than aluminum, 20% lower than copper

* Low heat resistance with flexible Graphite sheet*

* Low repulsion and easy to keep the product's shape after attaching

* RoHS, REACH compliant

* Siloxane Free

Parameters of natural graphite sheet:

TYPE | DSN60030 | DSN60050 | DSN60080 | DSN60100 | DSN60130 | DSN60150 |

Carbon Content | 99.80% | 99.80% | 99.80% | 99.80% | 99.80% | 99.80% |

Color | Dark Grey | Dark Grey | Dark Grey | Dark Grey | Dark Grey | Dark Grey |

Thickness (mm) | 0.03 | 0.05 | 0.08 | 0.1 | 0.13 | 0.15 |

Thickness Tolerance (mm) | ±0.005 | ±0.005 | ±0.01 | ±0.02 | ±0.02 | ±0.03 |

Density (g/cm³) | 1.5±0.1 | 1.5±0.1 | 1.5±0.1 | 1.4±0.1 | 1.3±0.1 | 1.3±0.1 |

Hardness (shore A) | 85 | 85 | 85 | 85 | 85 | 85 |

Tensile Strength (psi) | 650 | 650 | 650 | 650 | 650 | 650 |

UL Flammability Rating | 94VO | 94VO | 94VO | 94VO | 94VO | 94VO |

Temperature Range | -40ºCto400ºC | -40ºCto400ºC | -40ºCto400ºC | -40ºCto400ºC | -40ºCto400ºC | -40ºCto400ºC |

Thermal Conductivity(X-Y axis) | 400-500 W/m.K | 400-500 W/m.K | 350-450 W/m.K | 300-400 W/m.K | 300-400 W/m.K | 250-350 W/m.K |

Thermal Conductivity (Z axis) | 7~10 W/m.K | 7~10 W/m.K | 7~10 W/m.K | 7~10 W/m.K | 7~10 W/m.K | 7~10 W/m.K |

Thermal Resistance @100pis | 0.07ºC-in²/w | 0.08ºC-in²/w | 0.9ºC-in²/w | 0.1ºC-in²/w | 0.16ºC-in²/w | 0.2ºC-in²/w |

@681pis | 0.42ºC-in²/w | 0.51ºC-in²/w | 0.57ºC-in²/w | 0.66ºC-in²/w | 0.95ºC-in²/w | 1.07ºC-in²/w |

Volume Resistivity | 11*10-4 ohm-cm | 11*10-4 ohm-cm | 11*10-4 ohm-cm | 11*10-4 ohm-cm | 11*10-4 ohm-cm | 11*10-4 ohm-cm |

Outgassing TML | 0.15% | 0.15% | 0.15% | 0.15% | 0.15% | 0.15% |

Outgassing CVCM | 0.09% | 0.09% | 0.09% | 0.09% | 0.09% | 0.09% |

TYPE | DSN60200 | DSN60500 | DSN60800 | DSN61000 | DSN62000 | DSN63000 |

Carbon Content | 99.80% | 99.80% | 99.80% | 99.80% | 99.80% | 99.80% |

Color | Dark Grey | Dark Grey | Dark Grey | Dark Grey | Dark Grey | Dark Grey |

Thickness (mm) | 0.2 | 0.5 | 0.8 | 1.0 | 2.0 | 3.0 |

Thickness Tolerance (mm) | ±0.03 | ±0.05 | ±0.08 | ±0.1 | ±0.15 | ±0.15 |

Density (g/cm³) | 1.2±0.1 | 1.1±0.1 | 1.1±0.1 | 1.0±0.1 | 1.0±0.1 | 1.0±0.1 |

Hardness (shore A) | 85 | 85 | 85 | 85 | 85 | 85 |

Tensile Strength (psi) | 650 | 650 | 650 | 650 | 650 | 650 |

ULFlammability Rating | 94VO | 94VO | 94VO | 94VO | 94VO | 94VO |

Temperature Range | -40ºCto400ºC | -40ºCto400ºC | -40ºCto400ºC | -40ºCto400ºC | -40ºCto400ºC | -40ºCto400ºC |

Thermal Conductivity(X-Y axis) | 250-350 W/m.K | 250-350 W/m.K | 200-300 W/m.K | 100-200 W/m.K | 100-200 W/m.K | 100-200 W/m.K |

Thermal Conductivity (Z axis) | 7~10 W/m.K | 3~5 W/m.K | 3~5 W/m.K | 3~5 W/m.K | 3~5 W/m.K | 3~5 W/m.K |

Thermal Resistance @100pis | 0.25ºC-in²/w | 0.37ºC-in²/w | 0.5ºC-in²/w | 0.6ºC-in²/w | 0.77ºC-in²/w | 0.73ºC-in²/w |

@681pis | 1.16ºC-cm²/w | 1.3ºC-cm²/w | 1.58ºC-cm²/w | 1.7ºC-cm²/w | 1.93ºC-cm²/w | 1.88ºC-cm²/w |

Volume Resistivity | 11*10-4 ohm-cm | 11*10-4 ohm-cm | 11*10-4 ohm-cm | 11*10-4 ohm-cm | 11*10-4 ohm-cm | 11*10-4 ohm-cm |

Outgassing TML | 0.23% | 0.23% | 0.23% | 0.23% | 0.23% | 0.23% |

Outgassing CVCM | 0.16% | 0.16% | 0.16% | 0.16% | 0.16% | 0.16% |

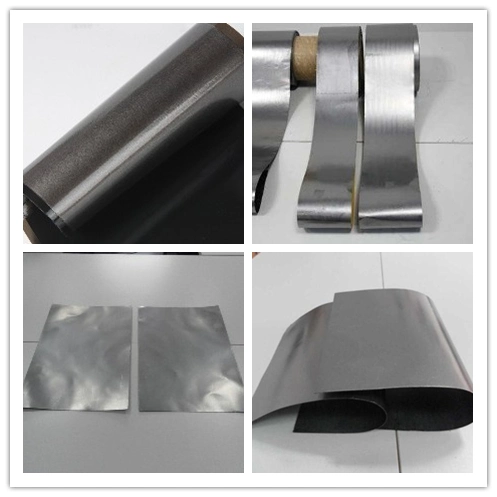

Product show:

Product application:

★ Widely used in metallurgical industry as refractories

★ Widely used in the electronics industry as the electrode conductive material

★ Water-resistant lubricating material

★ Anticorrosion materials in petroleum metallurgical industry

★ Used in a centrifugal pump and other equipment: make a pump or a seal

★ Used in an industrial furnace: make industrial furnace parts

★ The point solution process is used as an electrolytic plate: quality assurance

For below industries:

· High temperature furnace

· Metal industry

· Glass refractories

· Petrochemical industry

· Automobile industry

· Mechanical engineering

· Electric discharge

· Semiconductor industry

· Photovoltaic power generation

Contact us: Xingshi Graphite and Carbon

Mainly Products : Cathode carbon block , Specialty graphite parts , Graphite felts , Graphite Crucible , Graphite block , Graphite rod ..... Cold ramming paste , electrode paste , Refractory Materials ...